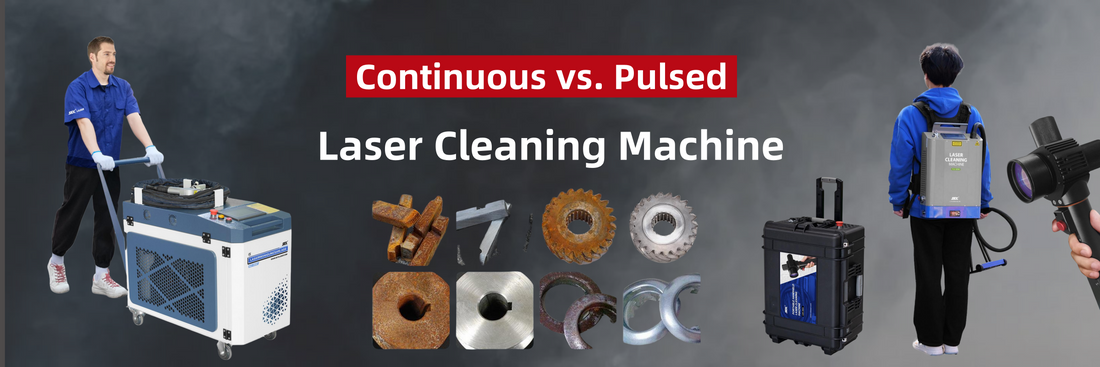

Laser cleaning technology has revolutionized various industries with its efficiency and precision. When it comes to laser cleaners, two prominent types dominate the market: pulsed lasers and continuous lasers. Both offer unique advantages and cater to different cleaning needs. Understanding their differences can help in selecting the right laser cleaner for specific applications. Here’s an in-depth look at the distinguishing features of pulsed and continuous laser cleaners.

Pulsed Laser Cleaners

Pulsed laser cleaners operate by emitting laser beams in short, high-energy bursts. These bursts, or pulses, are meticulously controlled to achieve optimal cleaning results without damaging the substrate. Here are the key features and benefits of pulsed laser cleaners:

1. Non-Contact 360° Cleaning: Pulsed lasers offer non-contact cleaning that can reach around the entire surface, regardless of space and location constraints. This method is environmentally friendly and doesn't require consumables.

2. Precision Control: The beam parameters of pulsed lasers can be finely tuned to avoid substrate heating and micro-melting. This precision ensures no damage to the underlying material, making it ideal for delicate surfaces.

3. High Cleanliness: Pulsed laser cleaning leaves surfaces exceptionally clean without any pollution or need for secondary treatment. The cleaned surfaces can be used immediately post-cleaning.

4. Ease of Operation: With red light focusing, the operation of pulsed lasers is straightforward. The system allows for automatic repeat cleaning, enhancing user convenience.

5. High Peak Power: Pulsed lasers boast a peak power ranging from 3 to 15 kw, delivering high cleaning efficiency. This makes them suitable for tough cleaning tasks.

6. Versatile Application: Pulsed lasers excel in cleaning coatings, plating, paint, rust, oil, oxidation layers, and materials requiring fine cleaning. They are particularly effective on surfaces that are high temperature, corrosion-resistant, and wear-resistant.

Continuous Laser Cleaners

Continuous laser cleaners, on the other hand, emit a constant stream of laser energy. This continuous operation mode offers several distinct advantages, especially for larger cleaning tasks:

1. Non-Contact 360° Cleaning: Like pulsed lasers, continuous lasers provide non-contact cleaning that isn't restricted by space or location. They are also environmentally friendly and free of consumables.

2. Higher Cleaning Efficiency: The option to use high-power lasers allows continuous cleaners to achieve higher cleaning efficiency. They can handle extensive cleaning tasks more quickly.

3. High Tolerance and Long Focus: Continuous lasers are highly tolerant and can maintain a long focus. This makes them convenient for cleaning large, irregular workpieces from a distance.

4. Precise Control: With red light assisted positioning, continuous lasers offer precise control and easy operation. This feature ensures accurate targeting of the cleaning area.

5. Automation Capability: Continuous lasers can be easily integrated with robotic systems, enabling fully automated cleaning processes. This integration enhances productivity and consistency.

6. Suitable for Large Areas: Continuous lasers are particularly effective for cleaning large areas, including paint, rust, oil, and oxide layers. Their high efficiency makes them ideal for extensive cleaning applications.

Choosing the Right Laser Cleaner

The choice between pulsed and continuous laser cleaners depends largely on the specific requirements of the cleaning task. Here’s a quick guide to help you decide:

For Delicate and Precise Cleaning: Pulsed lasers are the better choice. Their ability to finely control beam parameters and avoid substrate damage makes them ideal for sensitive surfaces and fine cleaning tasks.

For Large-Scale Cleaning: Continuous lasers are more suitable for extensive and large-area cleaning. Their high power and efficiency, combined with the ability to integrate with robotic systems, make them perfect for large and irregular surfaces.

Both pulsed and continuous laser cleaners offer non-contact, environmentally friendly cleaning solutions that are not constrained by space and location. Their unique features cater to different industrial needs, ensuring that there is a laser cleaning solution for virtually every application. Understanding these differences will enable you to select the most appropriate laser cleaner for your specific needs, optimizing both efficiency and effectiveness.

You can contact us directly by sending the material you need to clean and we will recommend the best model for your application.

Email: maggie@sfxlaser.com