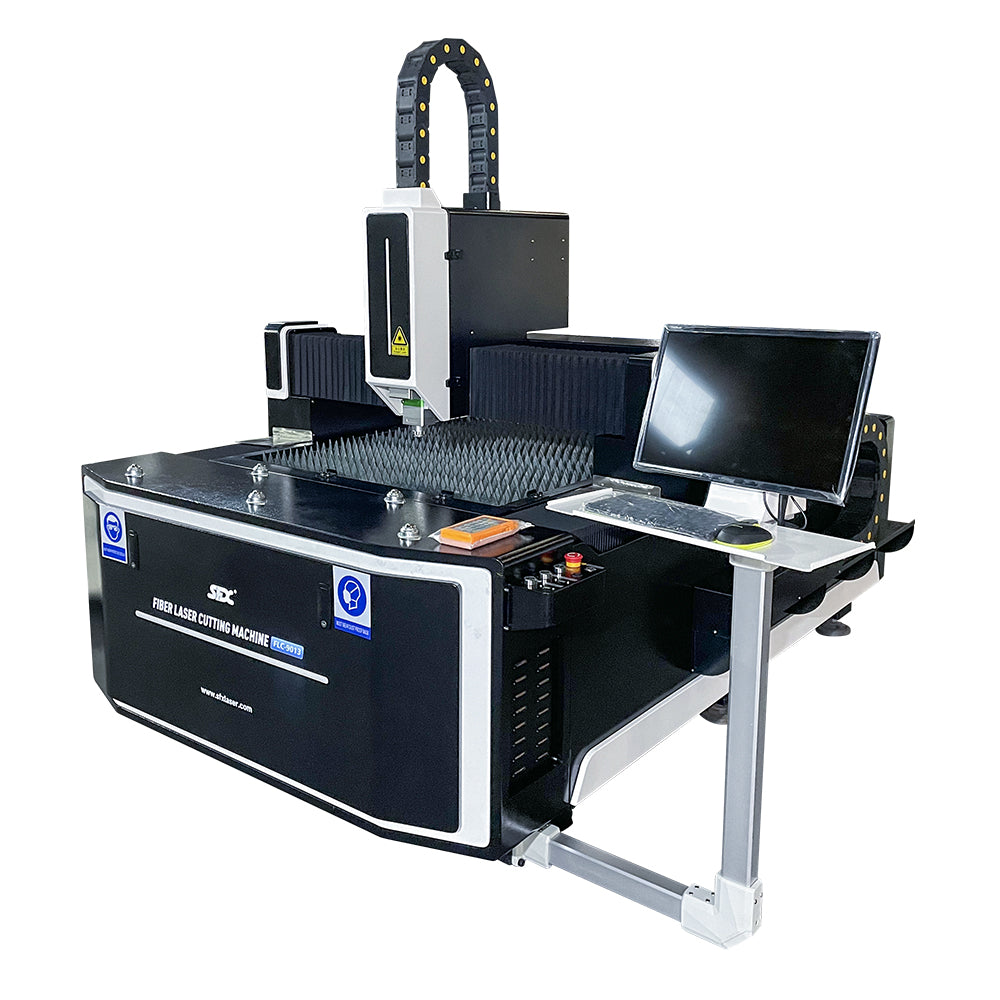

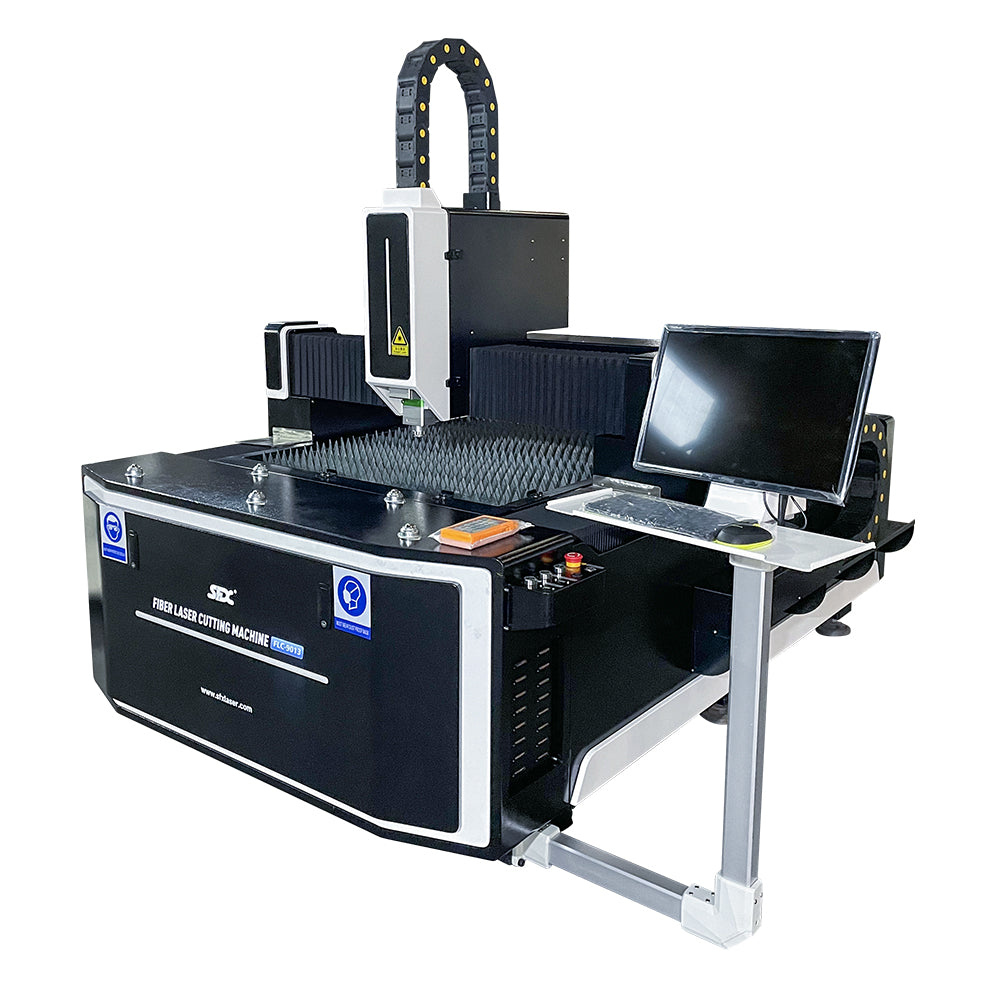

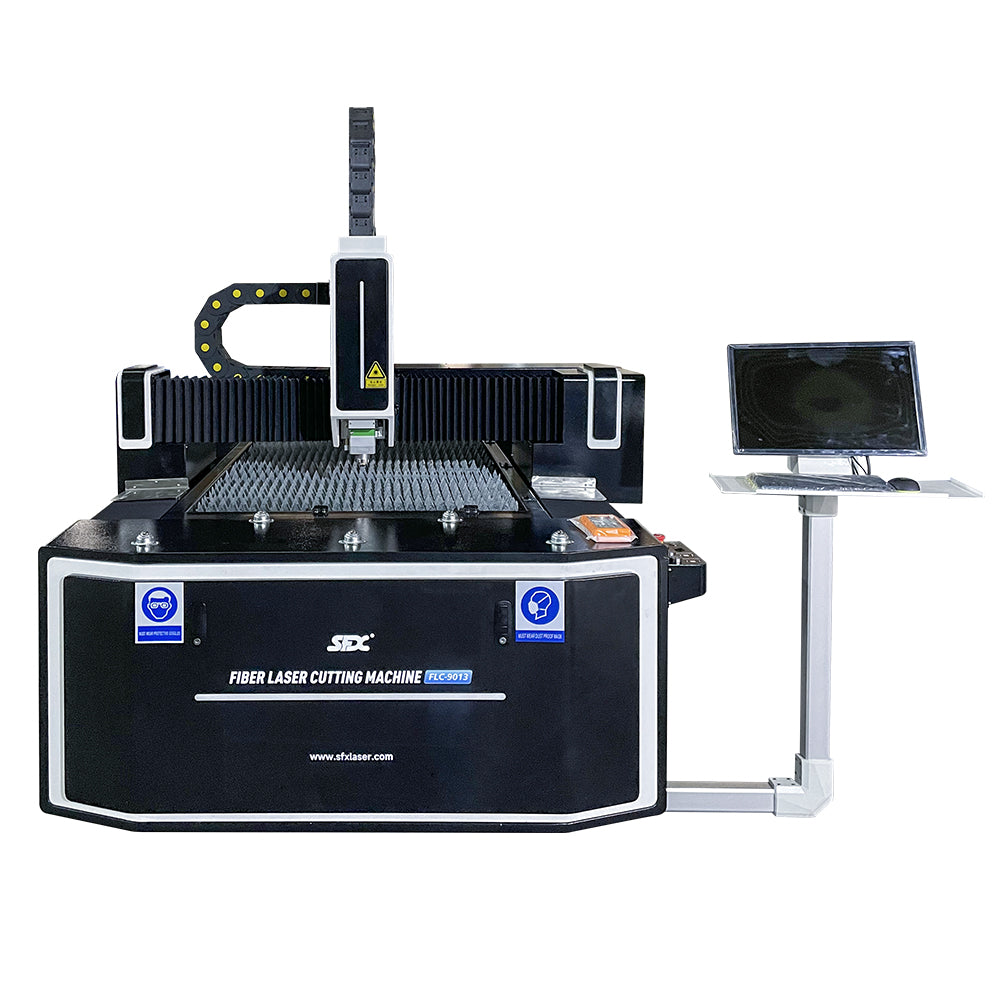

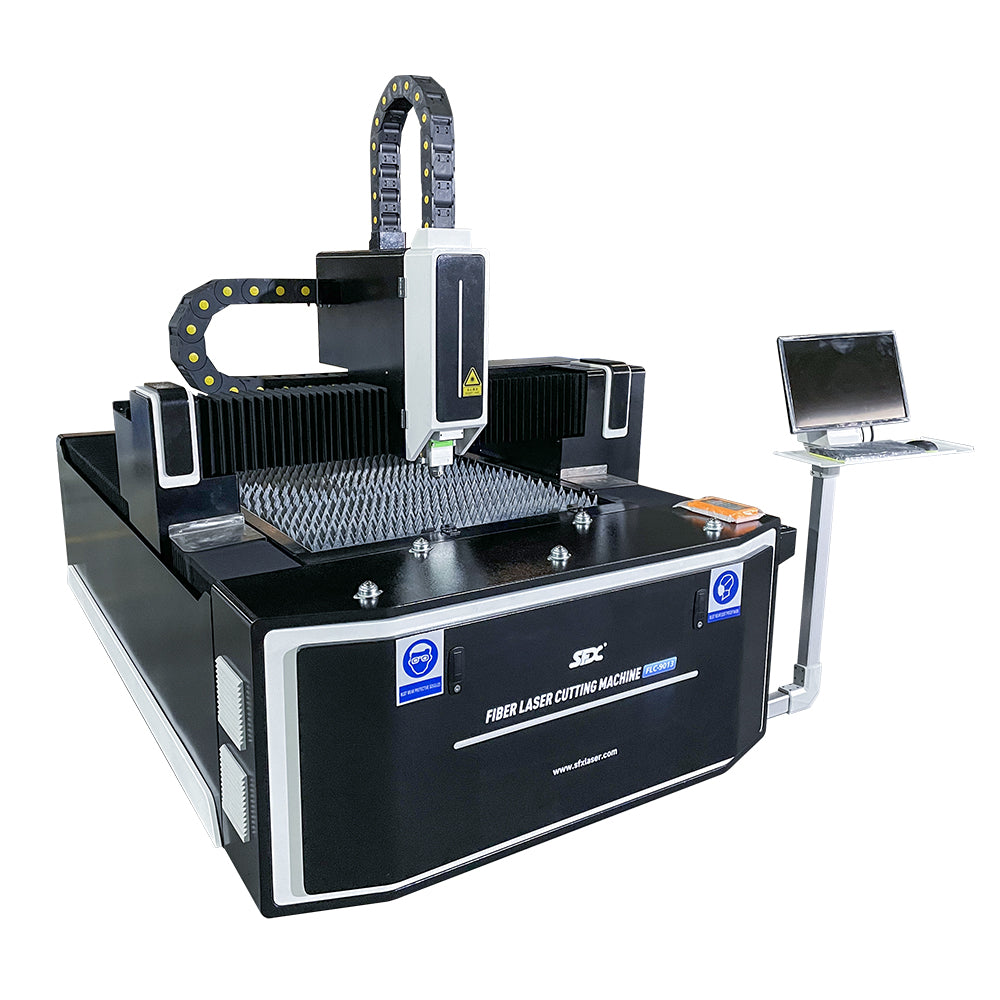

RAYCUS Fiber Laser Cutting Machine 900*1300mm Fiber Laser Cutter for Aluminum Copper Brass

RAYCUS Fiber Laser Cutting Machine 900*1300mm Fiber Laser Cutter for Aluminum Copper Brass

Couldn't load pickup availability

Shipping: FREE Shipping

Delivery: 40~50 days by Sea&Truck.

Handling time: Will ship within 5~7 business days of receiving full payment.

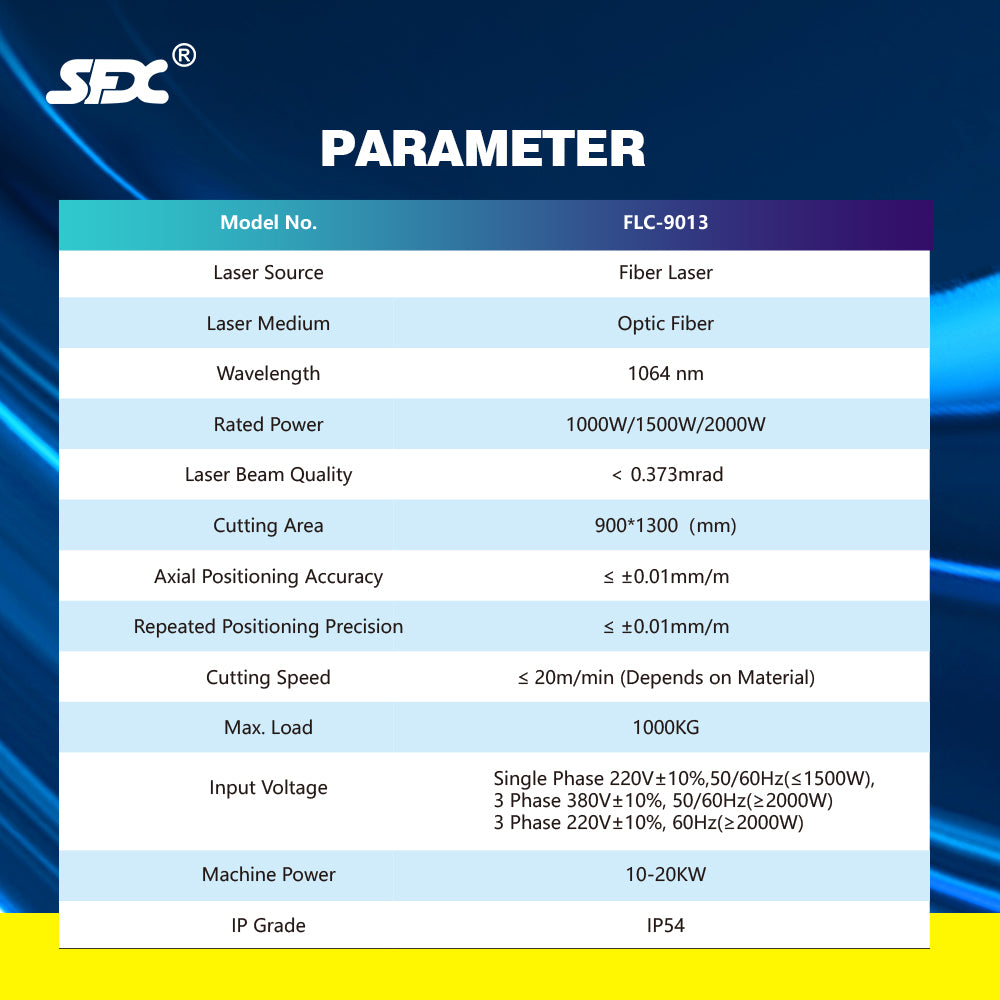

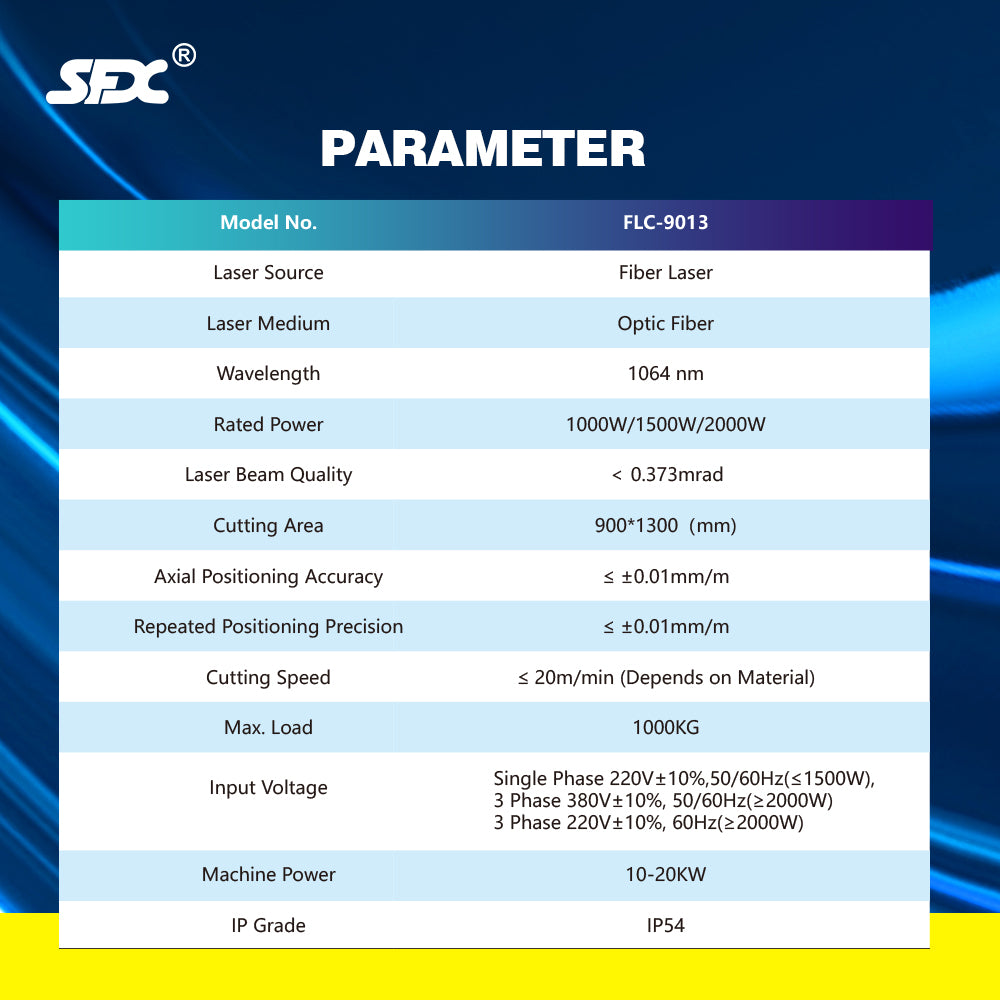

Technical Parameter

Model: FLC-9013

Laser Source: RAYCUS Fiber Laser

Laser Medium: Optic Fiber

Wavelength: 1064nm

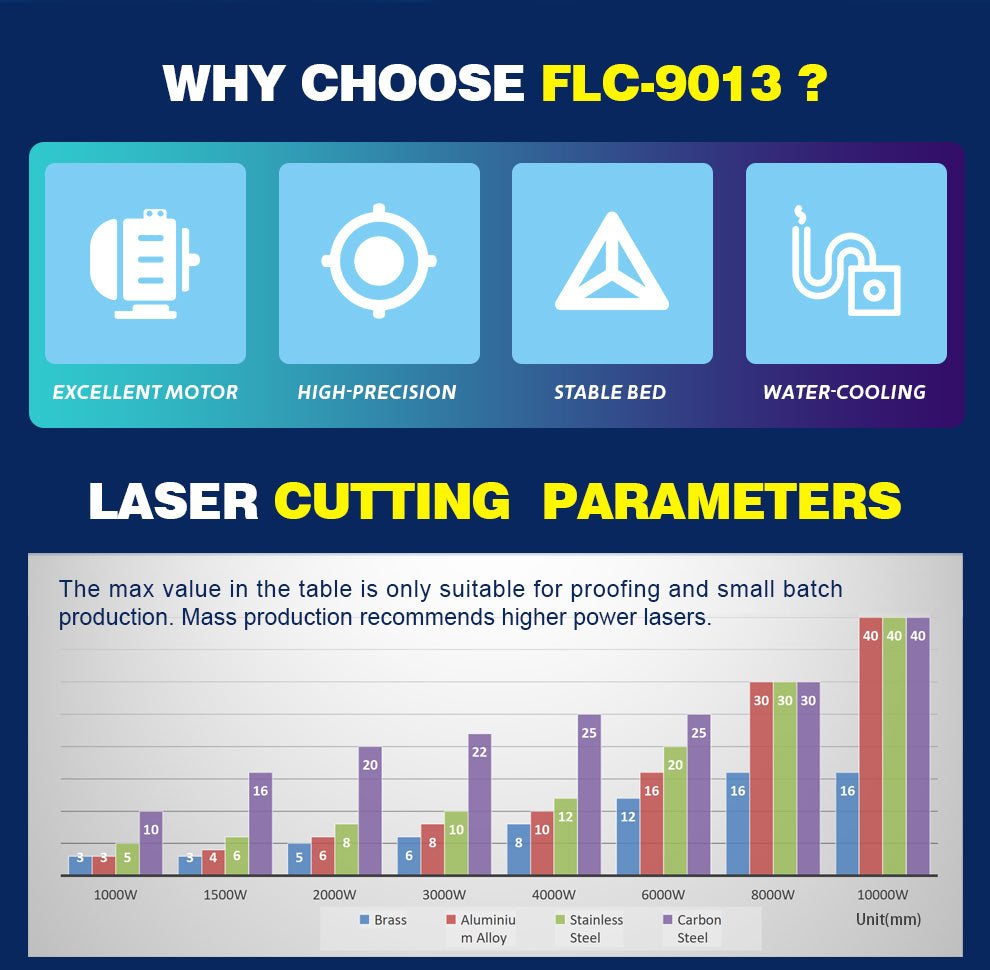

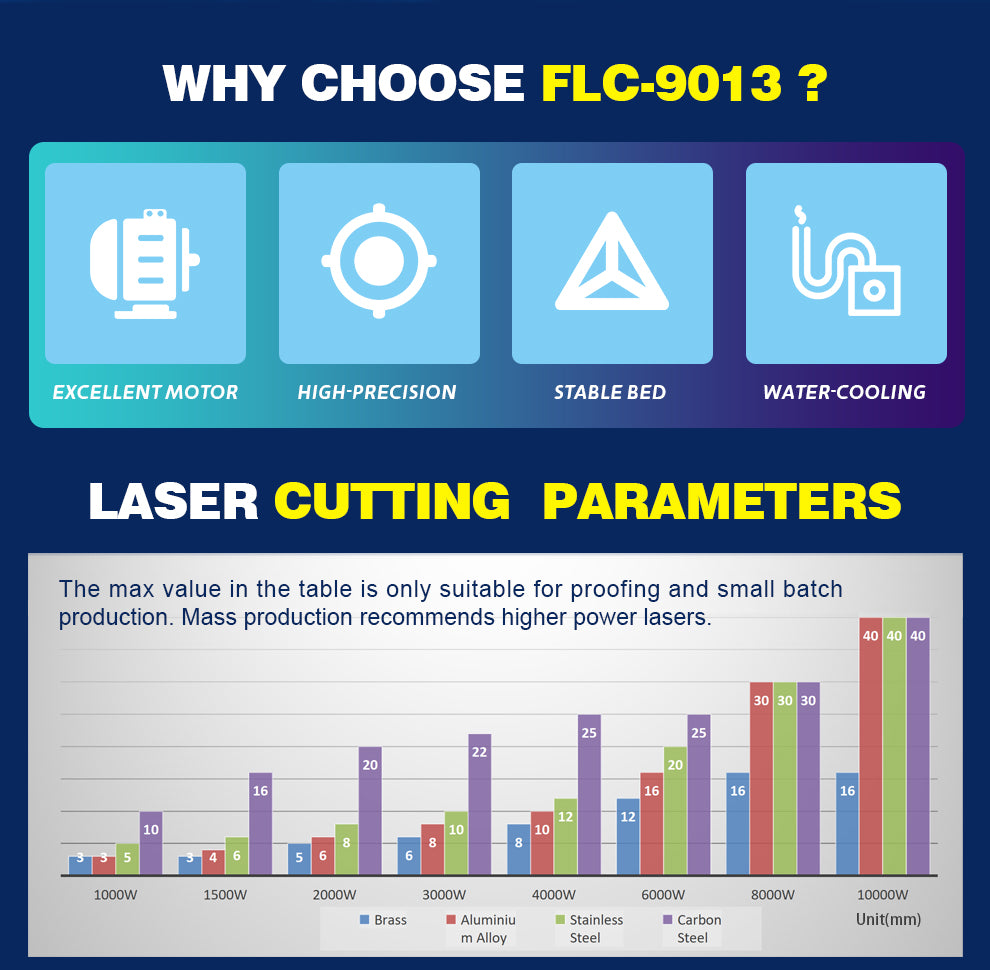

Rated Power: 1000W/1500W/2000W/3000W

Laser Beam Quality: <0.373mrad

Cutting Area: 900*1300mm

Axial Positioning Accuracy: ≤±0.01mm/m

Repeated Positioning Precision: ≤±0.01mm/m

Cutting Speed: ≤20m/min (Depends on Material)

Max. Load: 1000kg

Input Voltage: 380V 50Hz/240V 60Hz

Machine Power: 10-20KW

IP Grade: IP54

Laser Source

- RAYCUS laser source, the minimum service life exceeds 100,000 hours.

- The electrical-optical efficiency is high,saving a lot of maintenance expenses and time, and improving work efficiency.

- Stable performance,simple operation, simple field drawing can be performed.

- Supporting files:DXF, PLT, AI, LXD, etc.

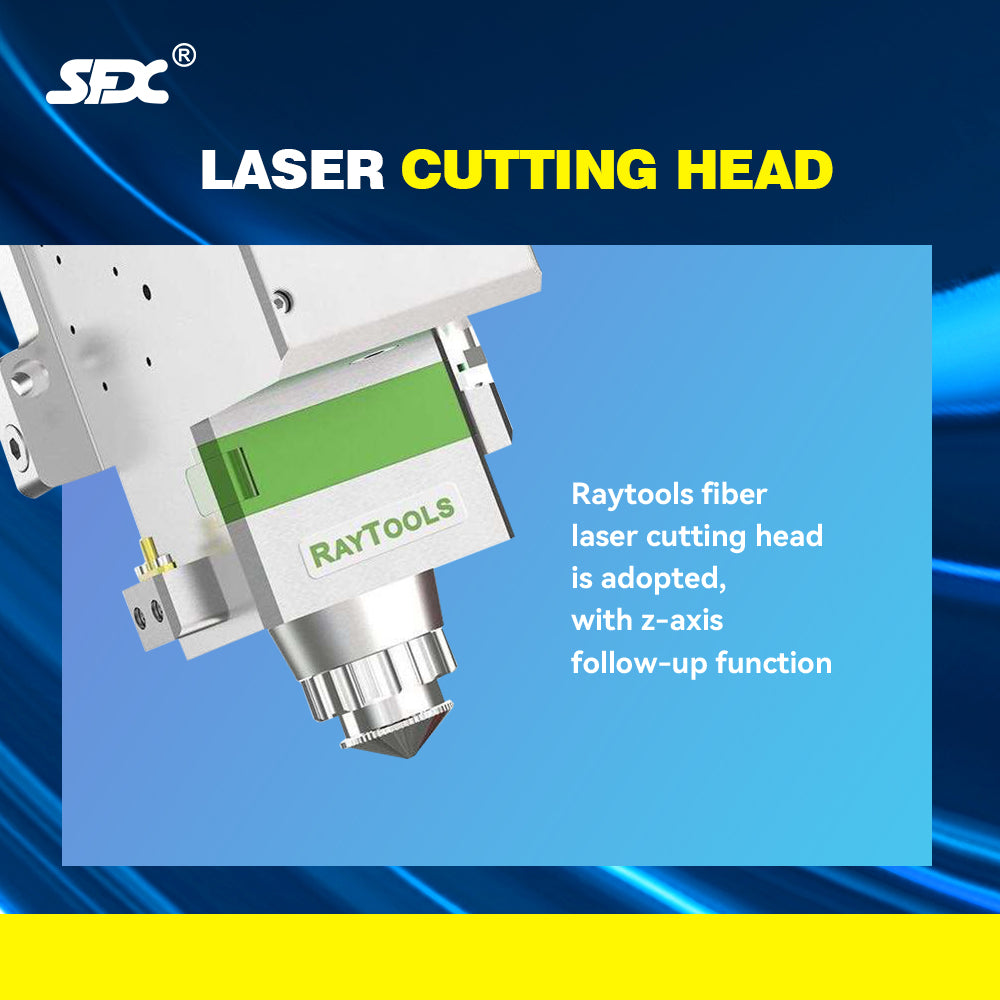

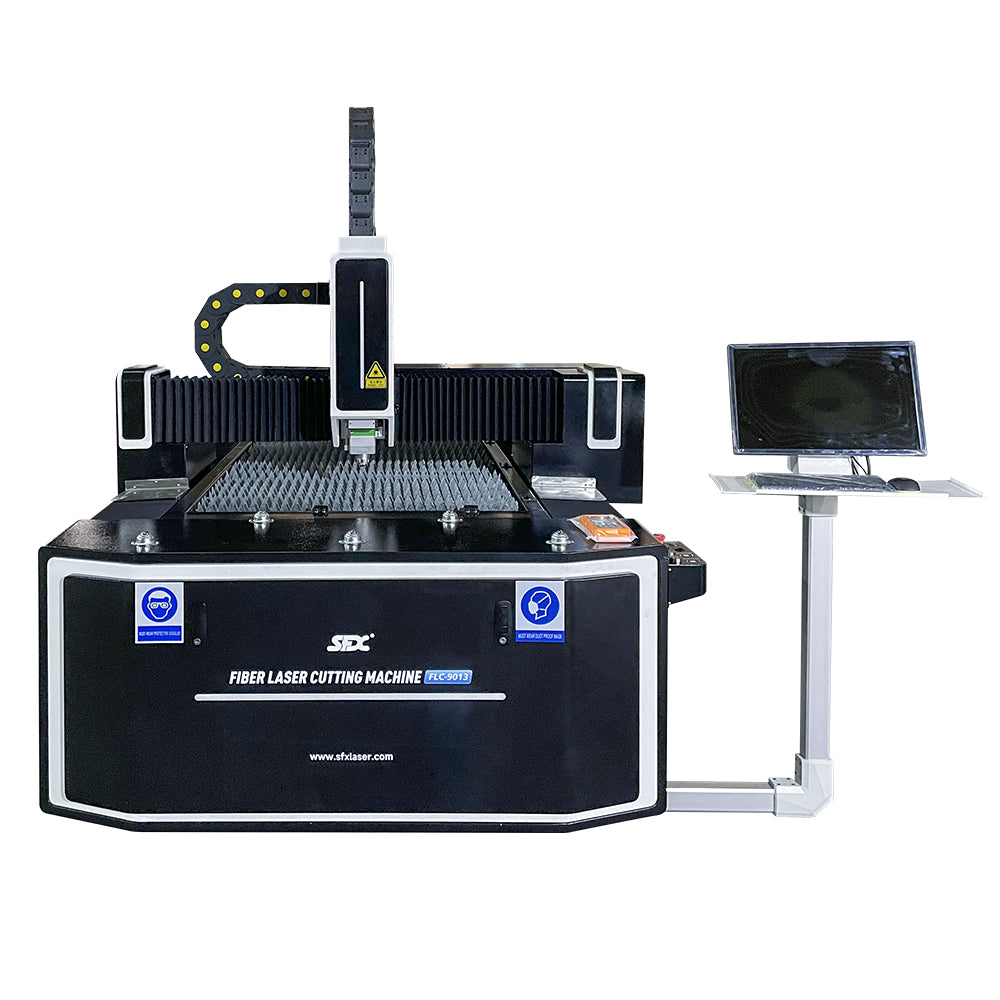

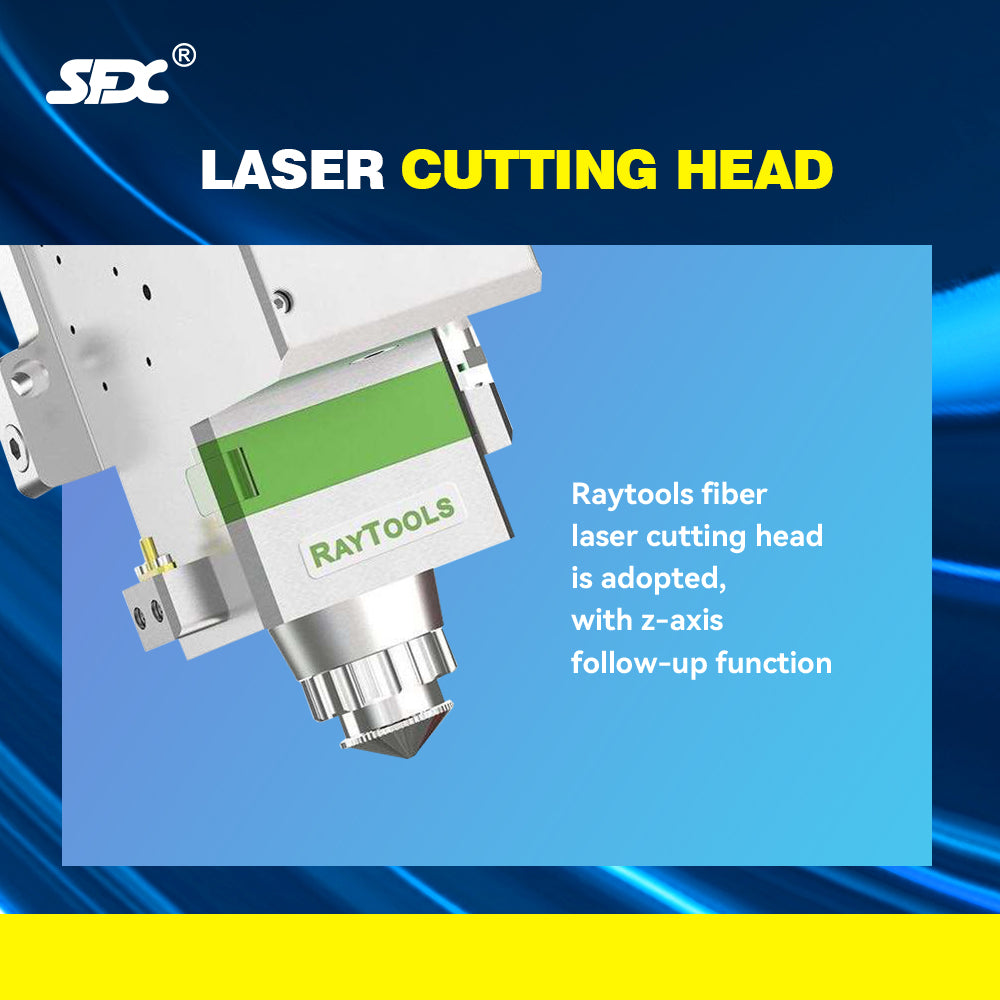

Laser Cutting Head

Raytools fiber laser cutting head is adopted, with z-axis follow-up function.

- The height follow-up sensing cutting head adopts capacitive sensing monitoring to provide stable and fast automatic adjustment function of cutting height.

- Various nozzle matching designs are suitable for lenses with various focal lengths. It can be equipped with optical lenses with different focal lengths.

- The focal length and nozzle height can be adjusted flexibly, including the coaxial adjustment of lens and nozzle in X-Y direction. The focal length of cutting head can be adjustedaccurately to 0.01mm.

High Precision Work Bed

Only with a solid bed can an efficient and high-precision cutting speed be ensured.

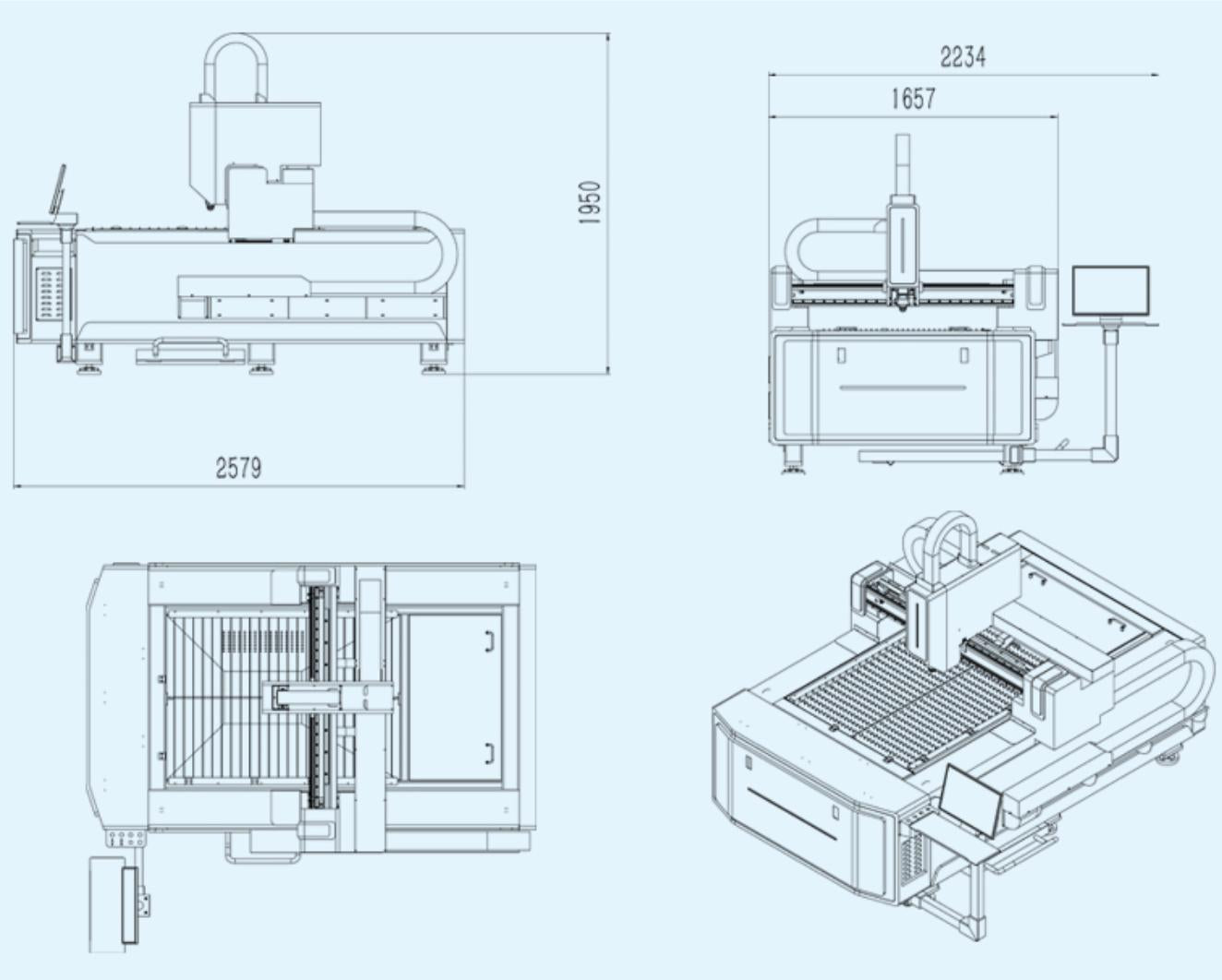

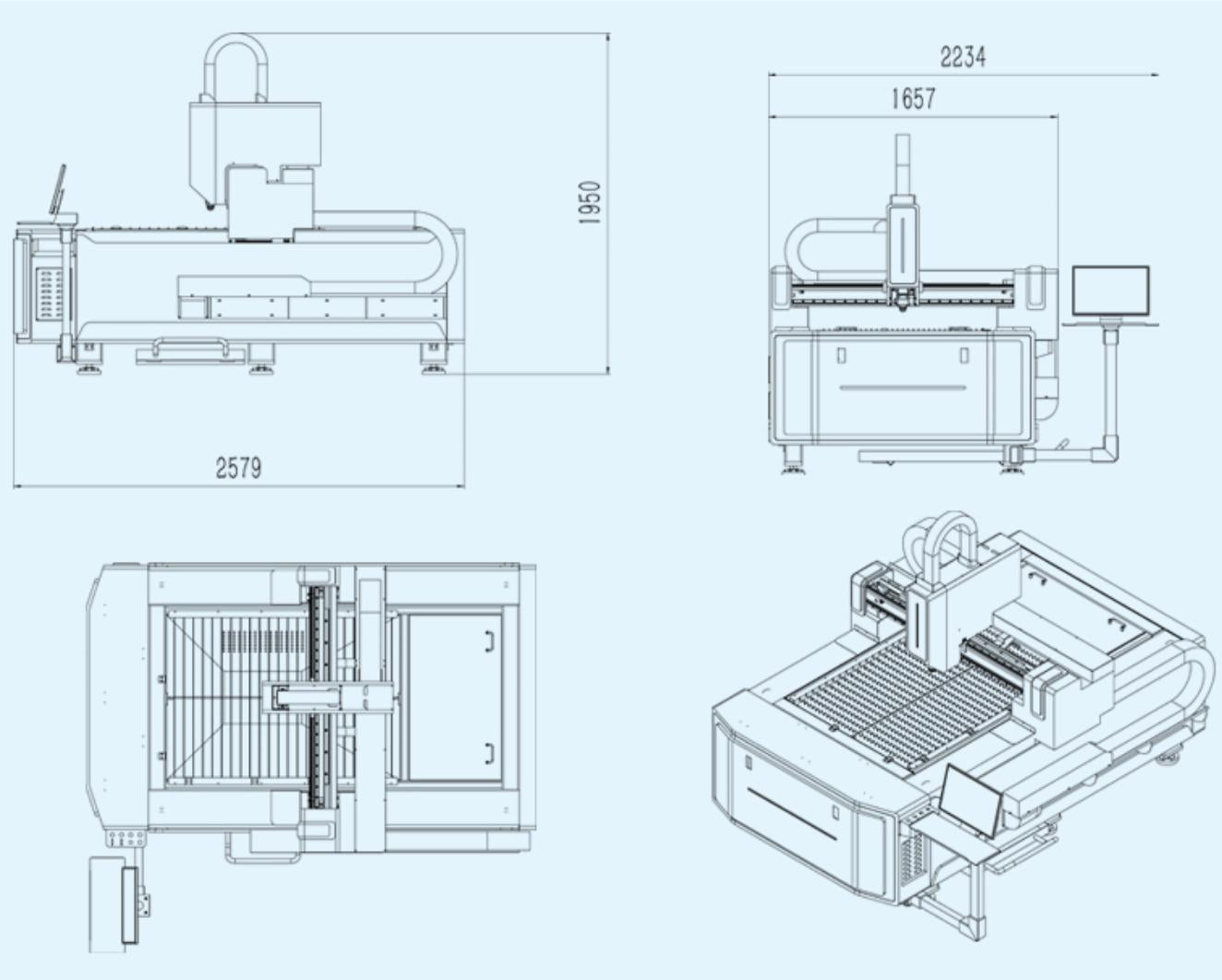

- The 9013 series cutting machine body is completely independently developed. The bed base is welded by a square tube and processed by a large gantry milling machine.

- We have many years of experience in machining large-scale machine beds. After rough machining, each bed will be placed for 30 to 45 days to fail naturally. After the internal stress is released, the finishing process will be carried out to ensure the machining accuracy!

- For each machine bed that leaves the factory, the guide rails are at a distance of 1.2 meters and the parallelism is less than 0.02mm.

- Safe and environmentallyfriendly, energy-saving and durable, stable working performance, long service life.

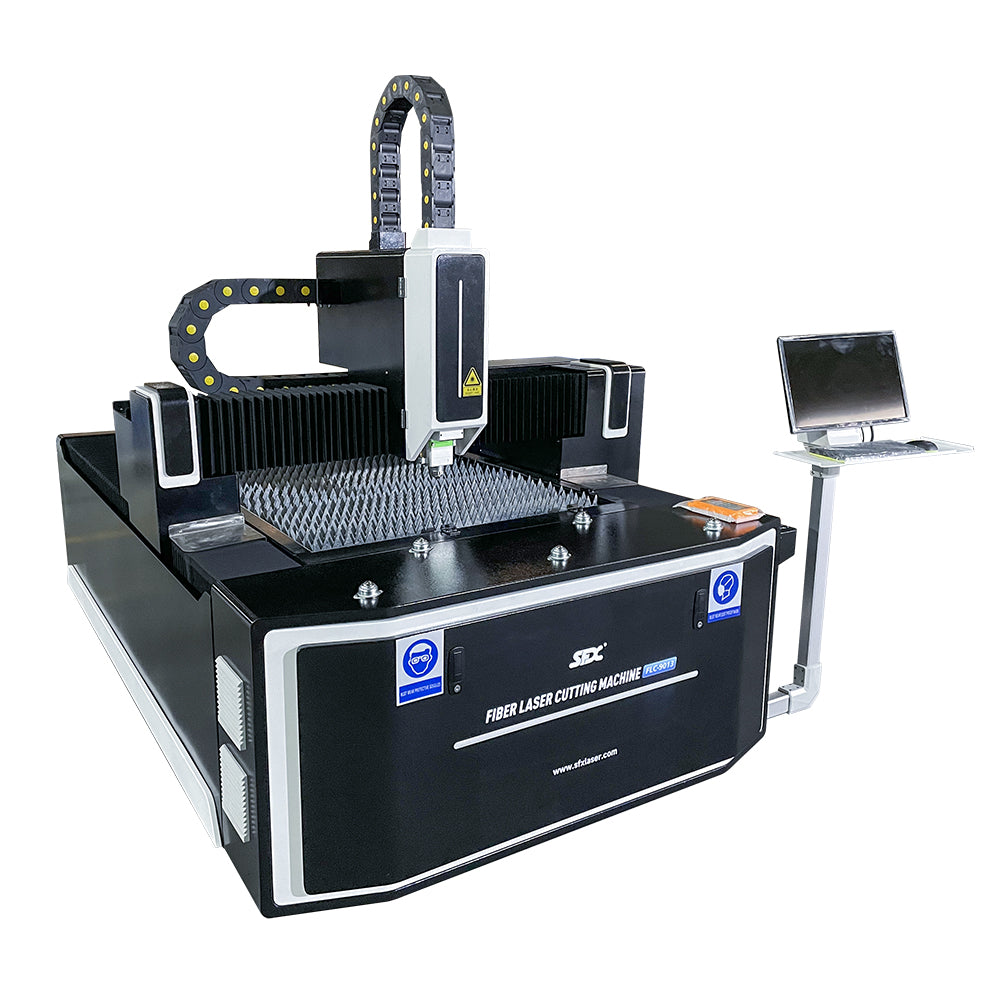

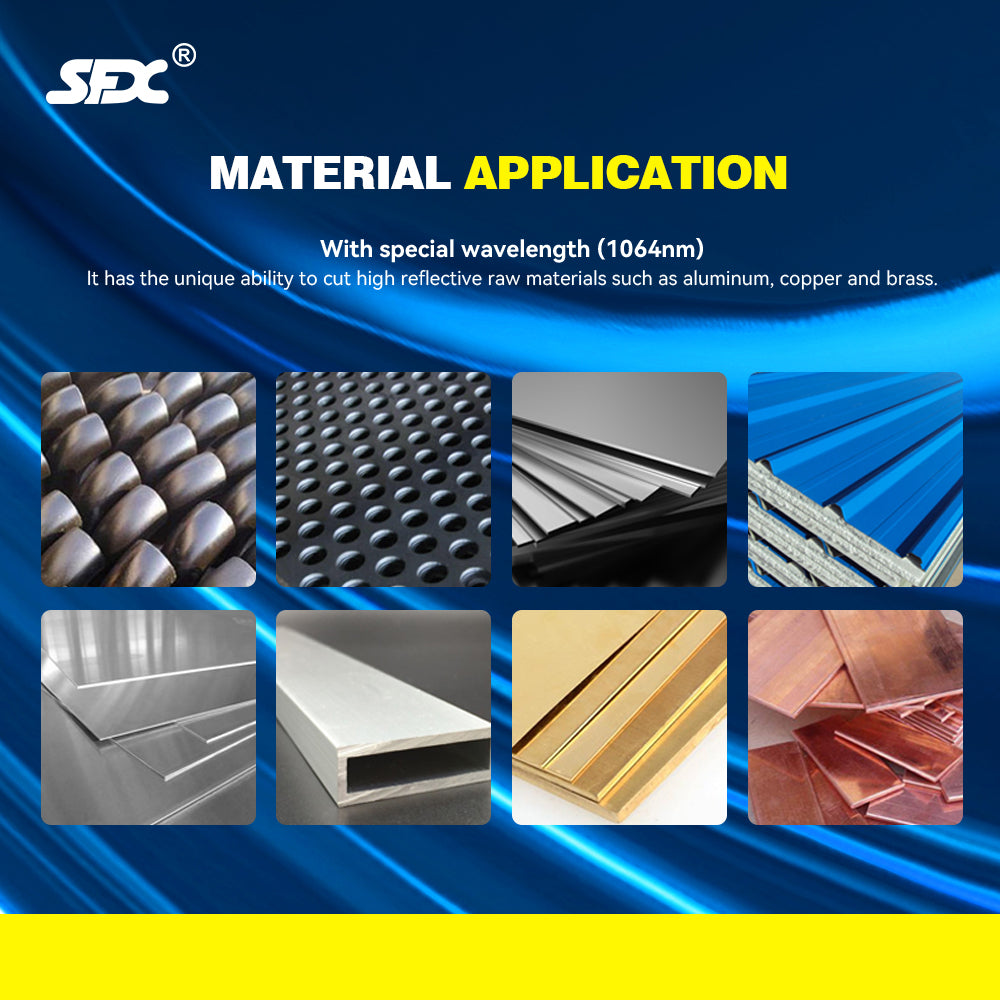

- With special wavelength (1064nm), it has the unique ability to cut high reflective raw materials such as aluminum, copper and brass.

- One year warranty for the whole machine and two years warranty for the laser source.

- We provide professional technical support. English user manual, operation video sending together with the machinery.During the warranty period, if the spare parts was sent back for repair, we will pay for the returning shipping cost and fees, repair them for free including the new parts that needed. (exclude wearing parts)

- We have after-sale service center in NY, US.

- We provide lifelong after-sales service and technical support.

Share