RAYCUS Precision Fiber Laser Cutting Machine Metal Laser Cutter 600*800mm

RAYCUS Precision Fiber Laser Cutting Machine Metal Laser Cutter 600*800mm

Couldn't load pickup availability

Shipping: FREE Shipping

Delivery: 40~50 days by Sea&Truck.

Handling time: Will ship within 5~7 business days of receiving full payment.

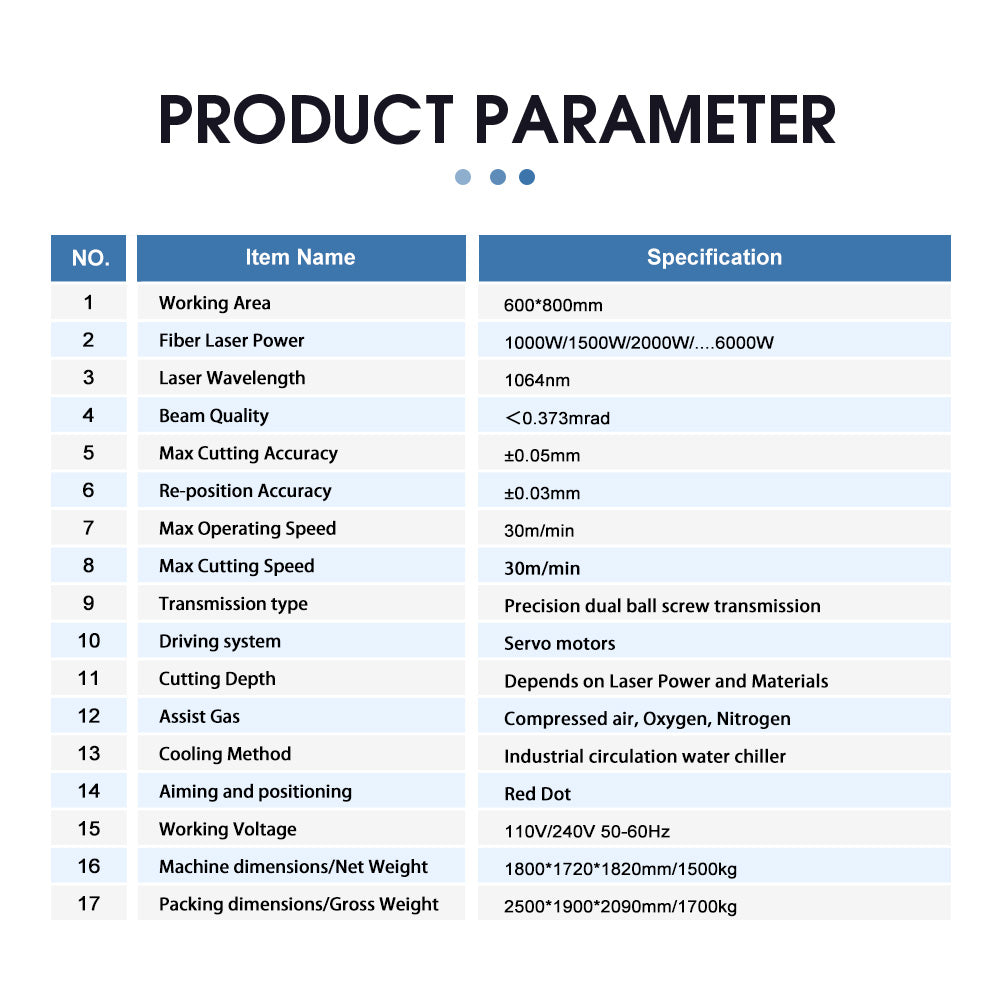

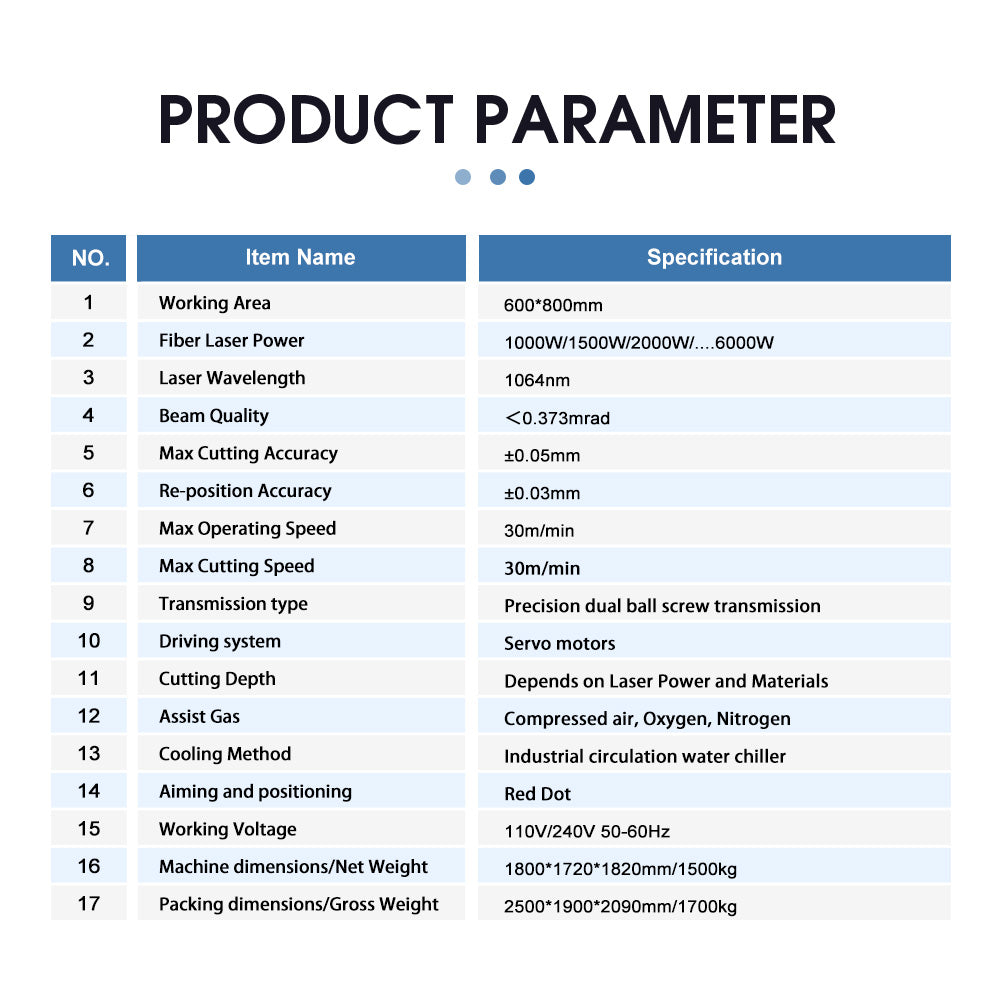

Technical Parameter

Working Area: 600*800mm

Fiber Laser Power: 1000W/1500W/2000W/3000W

Laser Wavelength: 1064nm

Beam Quality: <0.373mrad

Max Cutting Accuracy: ±0.05mm

Re-position Accuracy: ±0.03mm

Max Operating Speed: 30m/min

Max Cutting Speed: 30m/min

Transmission Type: Precision Dual Ball Screw Transmission

Driving System: Servo Motors

Cutting Depth: Depends on Laser Power and Materials

Assist Gas: Compressed Air, Oxygen, Nitrogen

Cooling Method: Industrial Circulation Water Chiller

Aiming and Positioning: Red Dot

Working Voltage: 110V/240V 50-60Hz

Machine Dimensions/Net Weight: 1800*1720*1820mm/1500kg

Packing Dimensions/Gross Weight: 2500*1900*2090mm/1700kg

RAYCUS LASER SOURCE

The minimum service life exceeds 100.000 hours.The electrical-optical efficiency is high, saving a lot of maintenance expenses and time,and improving work efficiency.

CYPONE/CYPCUT SOFTWARE SYSTEM

Stable performance, simple operation, simple field drawing can be performed.

Supporting files: DXF, PLT, Al, LXD, etc.

RAYTOOLS CUTTING HEAD

With Z-axis follow-up function. Stable and fast automatic adjustment of cutting height. Suitable for lenses with multiple focal lengths. The focal length and nozzle height can be adjusted flexibly, including the lens and nozzle coaxial adjustment in the X-Y direction, and the adjustment of the focal length of the cutting head can be accurate to 0.01mm.

PANASONIC SERVO MOTOR

Reliable wiring, oil-proof and dust-proof.

HANLI/S&A WATER CHILLER

Safe and environmentally friendly, energy-saving and durable, stable working performance, long service life.

REMOTE CONTROL

Easy and convenient to operate.

Automatic Oil

The supply of new oil can be maintained, can be stopped at any time, not controlled by the direction and position, accuracy is ensured, simple and flexible, and the trouble of oil cut can be avoided, and the cost of equipment maintenance can be reduced.

Marble Platform Machine Table

Adopt optical marble platform, anti-vibration frame design, good stability and precision, effectively eliminate the vibration generated in the cutting process.

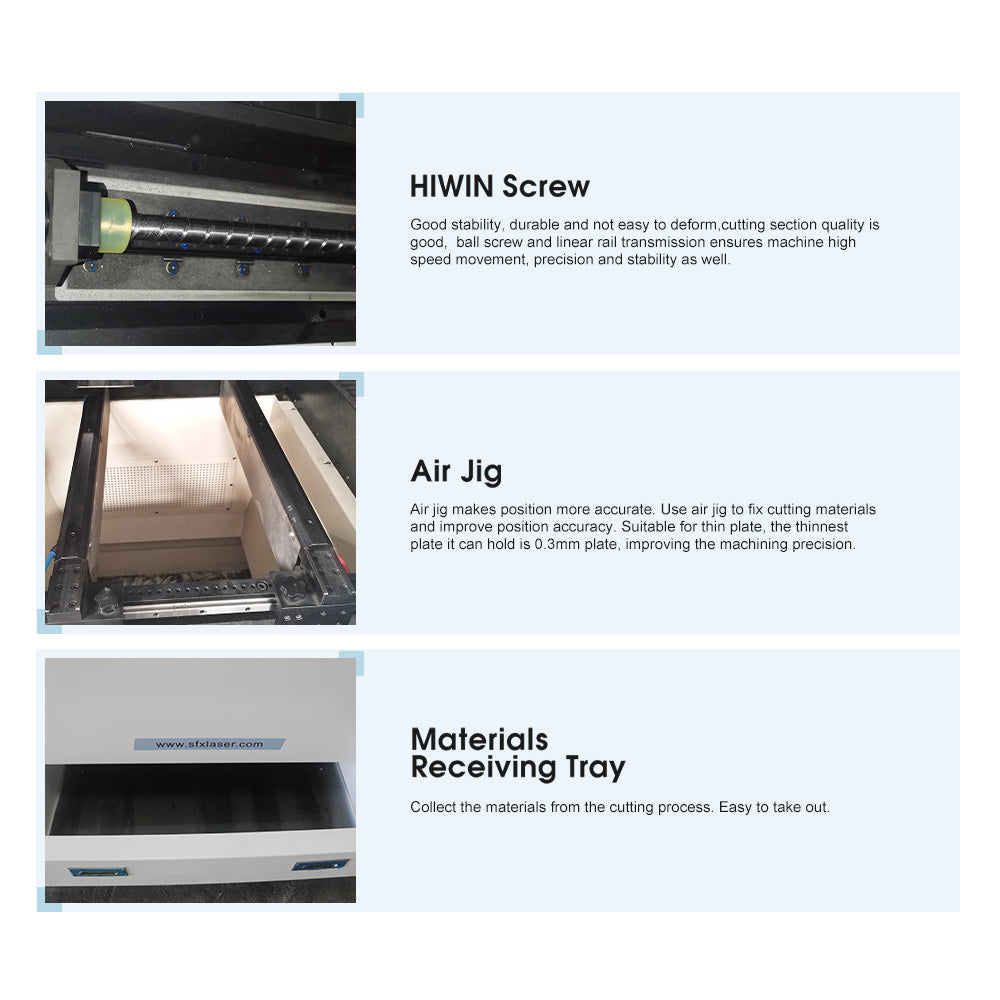

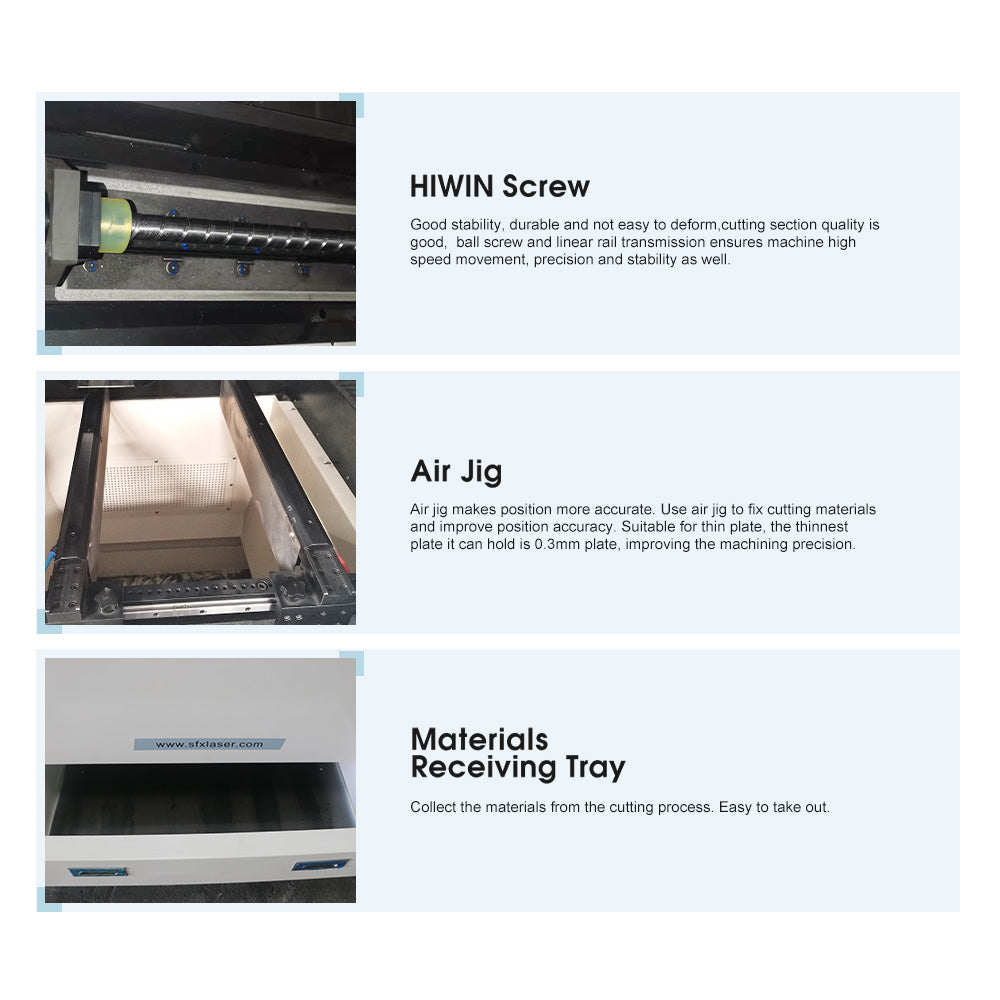

HIWIN Screw

Good stability, durable and not easy to deform, cutting section quality is good, ball screw and linear rail transmission ensures machine high speed movement, precision and stability as well.

Air Jig

Air jig makes position more accurate. Use air jig to fix cutting materials and improve position accuracy. Suitable for thin plate, the thinnest plate it can hold is 0.3mm plate, improving the machining precision.

Materials Receiving Tray

Collect the materials from the cutting process. Easy to take out.

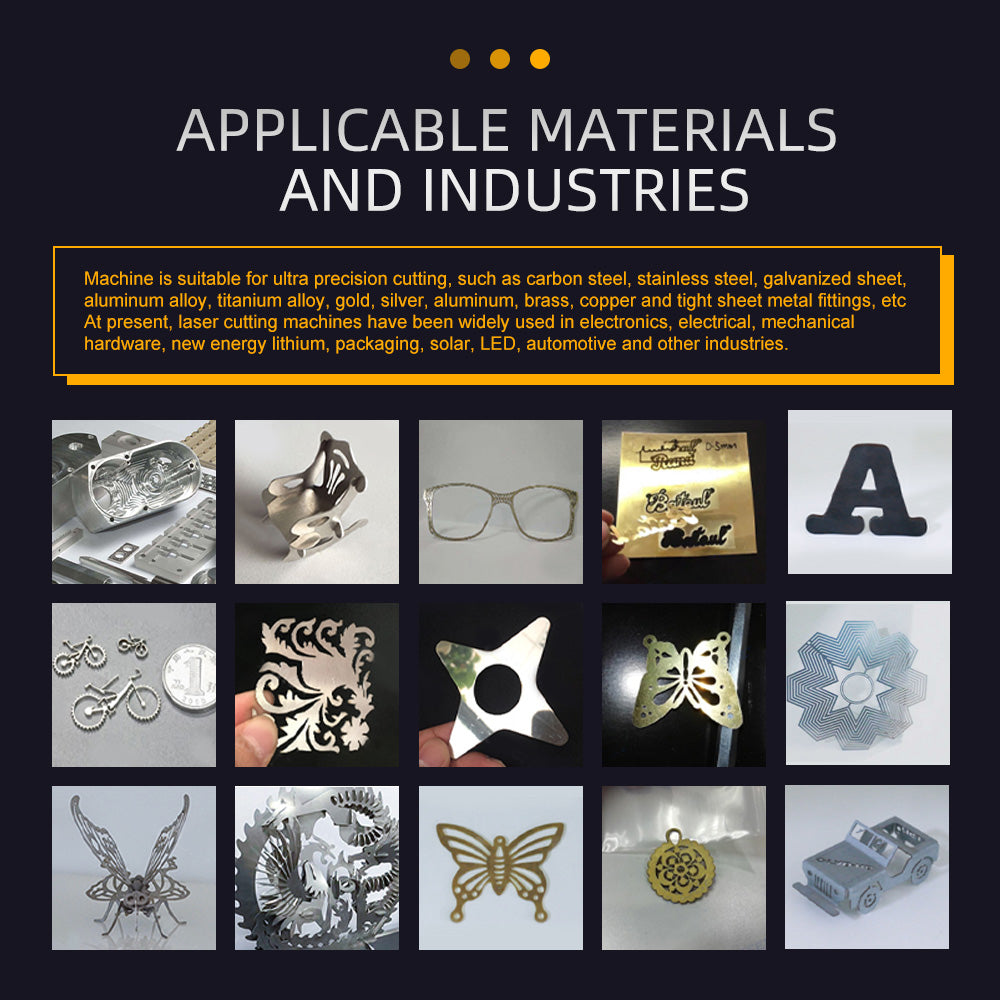

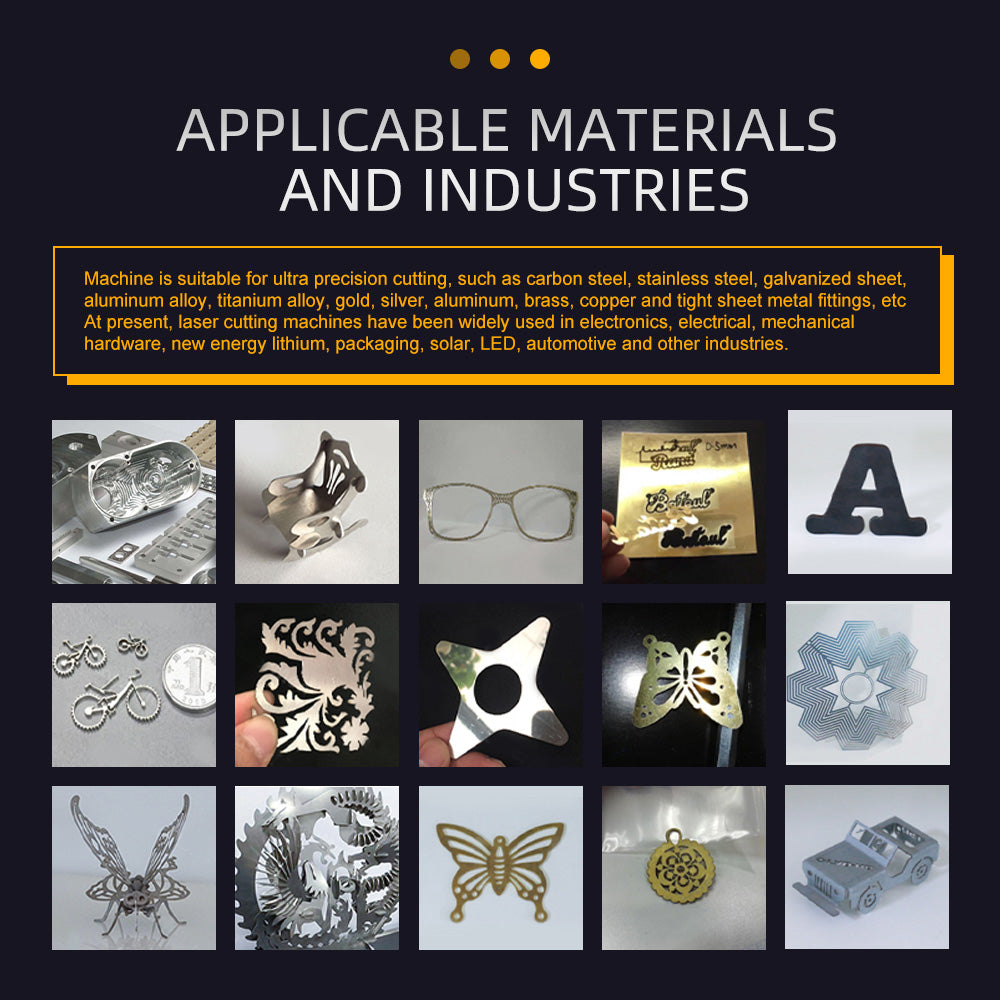

Applied Materials

Machine is suitable for ultra precision cutting, such as carbon steel, stainless steel, galvanized sheet, aluminum alloy, titanium alloy, gold, silver, aluminum, brass, copper and tight sheet metal fittings, etc.

Warranty

- One year warranty for the whole machine and two years warranty for the laser source.

- We provide professional technical support. English user manual, operation video sending together with the machinery.During the warranty period, if the spare parts was sent back for repair, we will pay for the returning shipping cost and fees, repair them for free including the new parts that needed. (exclude wearing parts)

- We have after-sale service center in NY, US.

- We provide lifelong after-sales service and technical support.

Share