SFX Handheld Fiber Laser Welding Cleaning 2 in 1 Machine 1500W/2000W/3000W Laser Welder

SFX Handheld Fiber Laser Welding Cleaning 2 in 1 Machine 1500W/2000W/3000W Laser Welder

Couldn't load pickup availability

Free Shipping to Door. Fast Delivery DHL/UPS/FedEx.

**Reminder for Laser Equipment**: Summer Heat Protection and Winter Freeze Prevention.

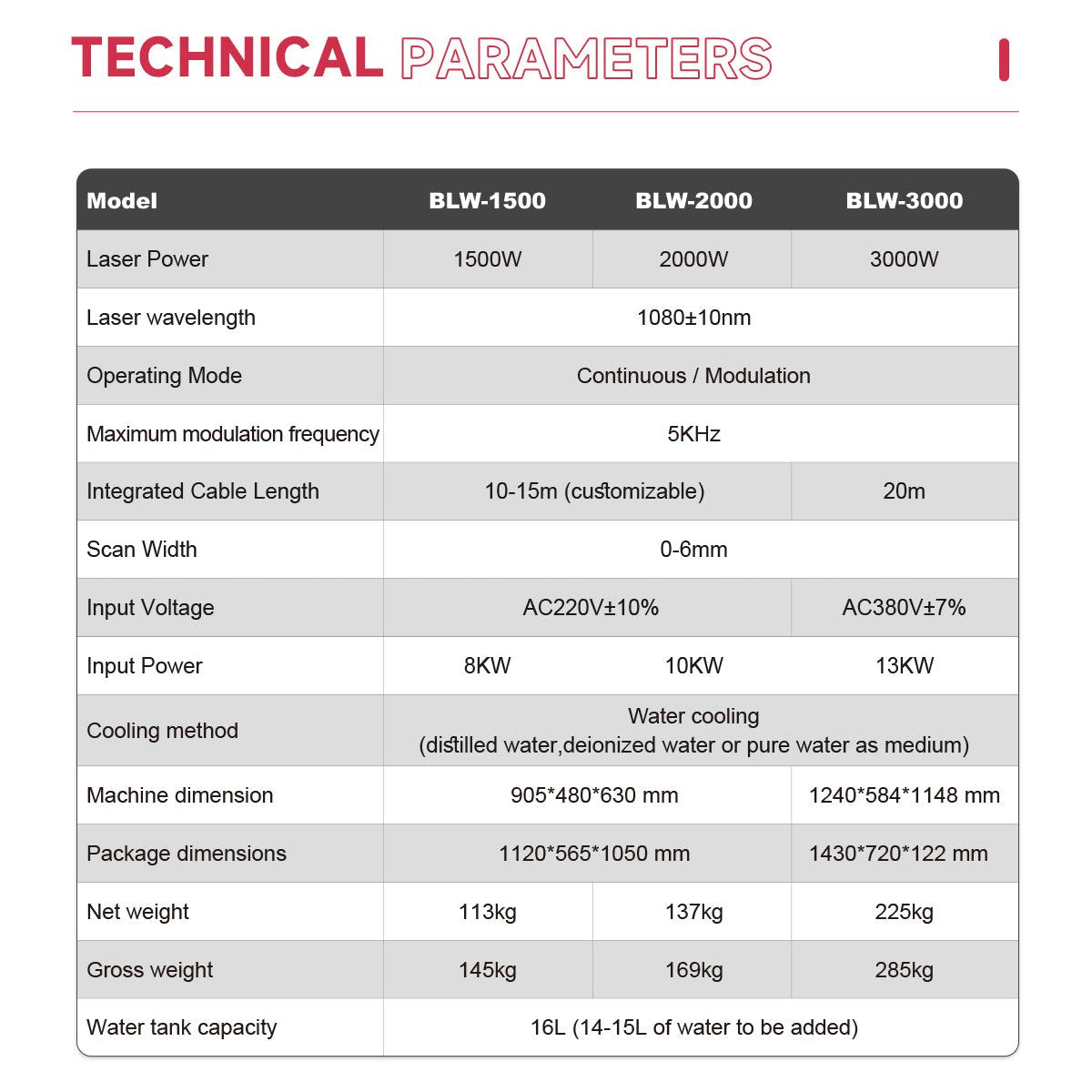

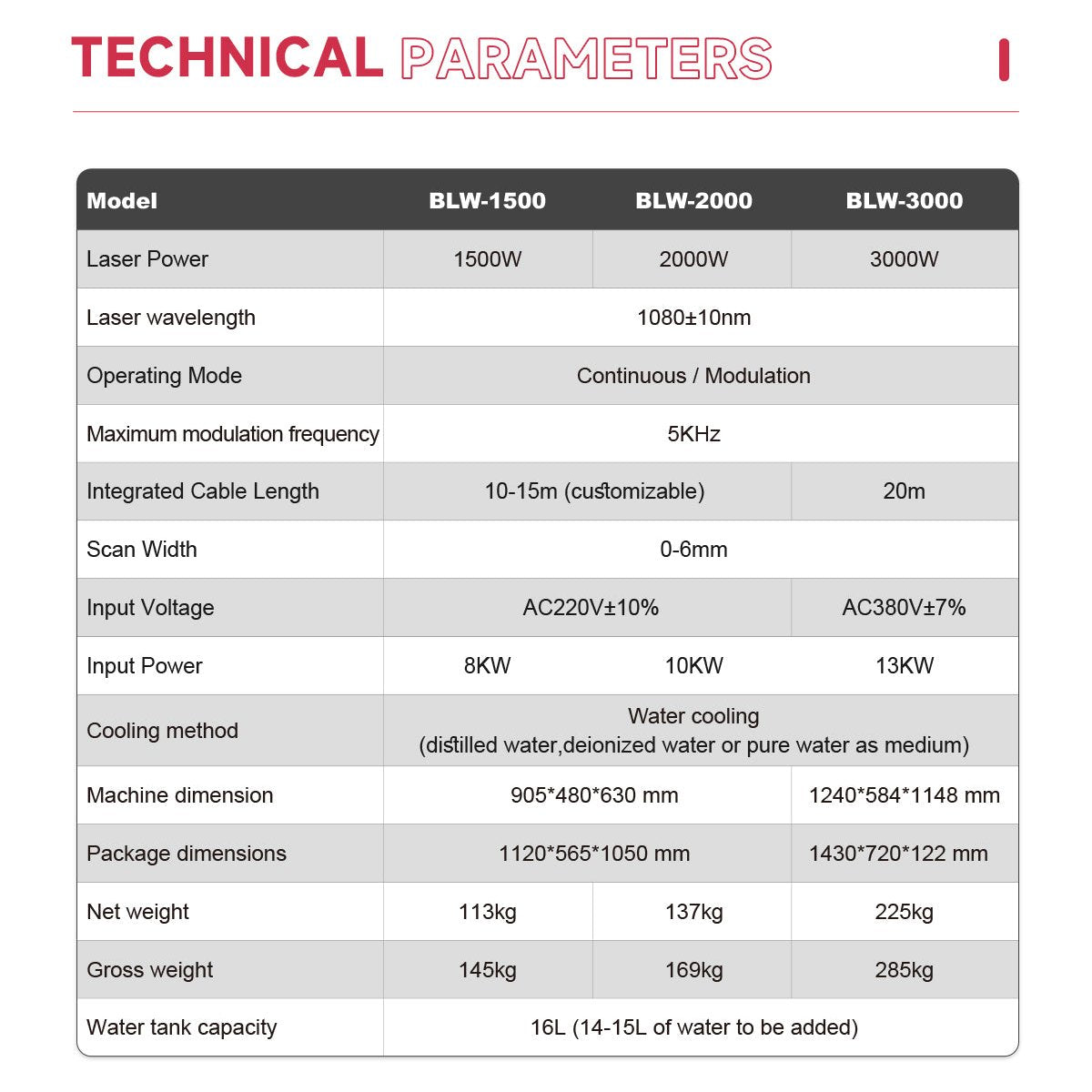

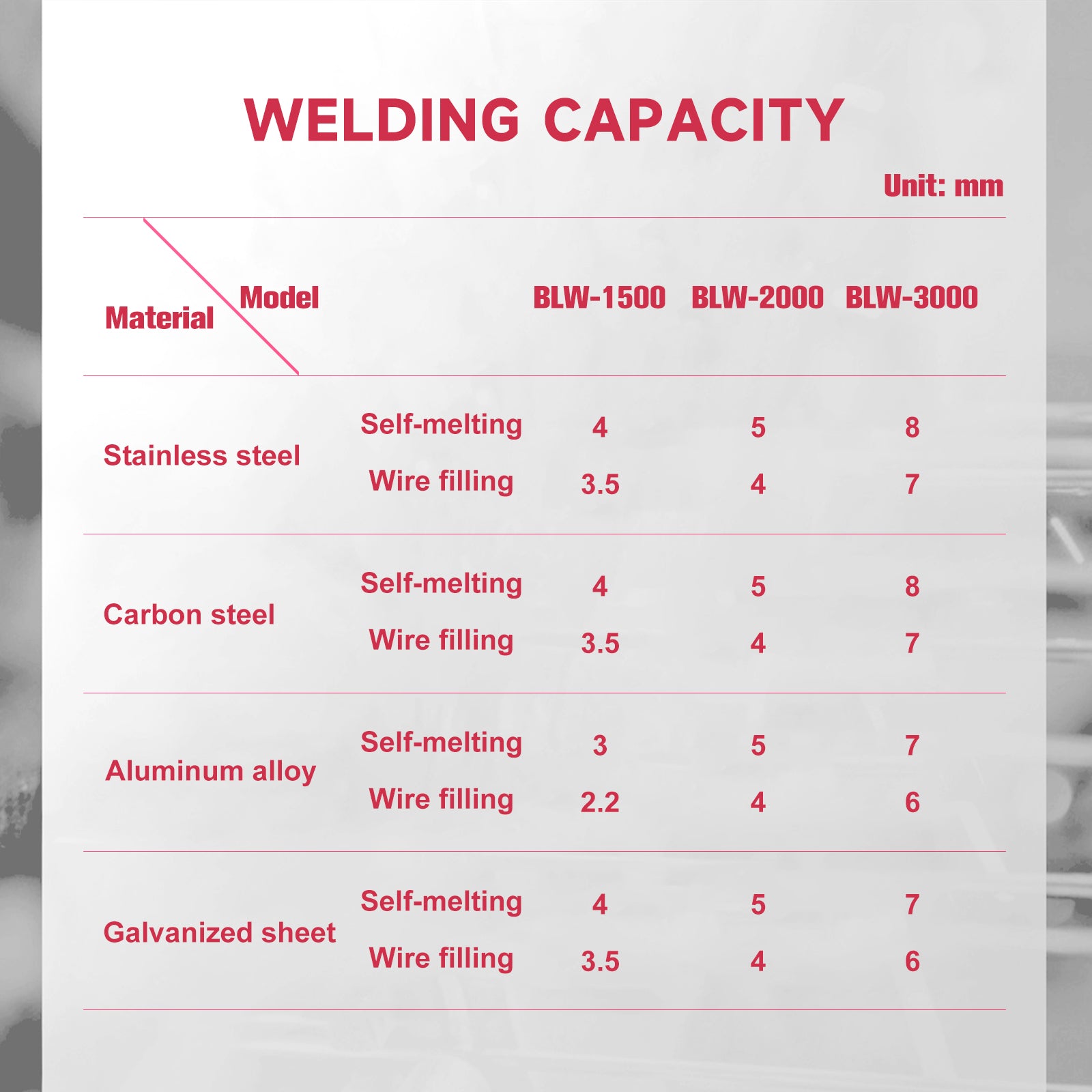

Technical Parameter

Model: BLW-1500/BLW-2000/BLW-3000

Laser Type: MAX Fiber laser, 1080±10nm.

Laser Power: 1500W/2000W/3000W

Integrated Cable Length: Standard 10m (Customizable 15m)

Maximum Modulation Frequency: 100KHz

Scan Width: 0-6mm

Cooling Method: Water Cooling (Distilled water, deionized water or pure water as medium.)

Operating Mode: Continuous or Modulated

Visual Positioning: Red Dot

Water Tank Capacity: 16L (14-15L water need to be added.)

Machine Dimension: 845*460*605mm/905*480*630mm/1260*590*1190mm

Package Dimension: 1270*580*1070mm/1350*705*1325mm

Net Weight: 110kg/135kg/229kg

Gross Weight: 160kg/185kg/277kg

Input Voltage: AC220V±10%, single phase( 1500W/2000W); AC380V±7%, 3 phase, transformer included(3000W).

Product Advantages

- Handheld welding gun

Pure copper welding nozzle,Integrated gas protection system

The hand-held welding head is light and flexible, which can realize welding of any part of the workpiece. You are not easy to fatigue after a long working time.

- Integratedwater-cooler chassis

Industrial grade design. Tailor-made for special purpose, thickened sheet metal structure, firm and anti-deformation, efficient heat dissipation, cost reduction by mass production.

Ergonomic design, easy to push.

Self-adaptive speed fan, direct cooling and heat dissipation. High Efficiency and Energy Saving.

Four sides can be opened, with compact structure and simple maintenance.

- MAX Laser source

High stability, power saving and basically maintenance-free Effectively reduce the cost of equipment use Optimize the user experience.

- Smart control panel

Full touch screen operation interface, multilingual support. Work status is clear at a glance. Process library design, set once, use at any time.

- Auto wire feeder

When the welding gap is big or you want a stronger welding strength, wire feeder is needed. You can turn off the feeder function when you do not need it.

Applicable Industry

It is widely used in the complicated and irregular welding processes of cabinets and kitchens, stair lifts, shelves, ovens, stainless steel doors and windows guardrails, distribution boxes, stainless steel furniture, metal sheet metal and other industries.

Warranty

- One year warranty for the whole machine and two years warranty for the laser source.

- We provide professional technical support. English user manual, operation video sending together with the machinery. During the warranty period, if the spare parts was sent back for repair, we will pay for the returning shipping cost and fees, repair them for free including the new parts that needed. (exclude wearing parts)

- We have after-sales service centers in the United States and Canada.

- We provide lifelong after-sales service and technical support.

Share