The Small Air-Cooled Laser Welding Machine is designed with cutting-edge technology to simplify and enhance the welding process. Its integrated air-cooled design ensures that the machine remains maintenance-free, allowing users to focus on their work without worrying about frequent upkeep. This high level of integration also means the machine is easy to carry, making it an ideal choice for both stationary and mobile welding tasks.

Lightweight Gun Head: Ergonomic and Efficient

One of the standout features of this laser welding machine is its lightweight gun head. Weighing only 650 grams, the handheld design significantly reduces operator fatigue, enabling longer periods of use without discomfort. This ergonomic design not only enhances user comfort but also improves overall welding precision and efficiency.

Unmatched Welding Speed

When it comes to speed, the Small Air-Cooled Laser Welding Machine outperforms traditional welding methods by a considerable margin. Capable of welding 4 to 10 times faster than conventional techniques, this machine drastically reduces production time while maintaining high-quality results. Whether you're working on large-scale projects or quick repairs, this machine ensures you complete your tasks faster than ever before.

Highly Intelligent and User-Friendly

This laser welding machine is designed with user-friendliness in mind. Its highly intelligent system is easy to operate, even for those without prior welding experience. The machine comes with 14 sets of customized and 40 sets of prefabricated process parameters, allowing users to get started quickly, often within just 30 minutes. This intelligent setup ensures that users can achieve professional results with minimal training.

Exquisite Weld Seam: No Polishing Required

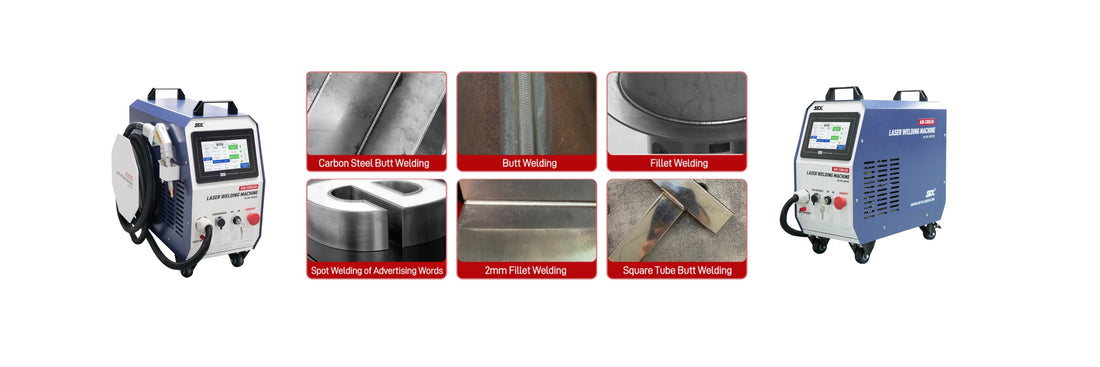

The quality of the weld seam produced by the Small Air-Cooled Laser Welding Machine is exceptional. Thanks to its advanced technology, the machine delivers exquisite weld seams that typically require no additional polishing. Depending on the material and thickness, welding process parameters can be quickly and easily selected to ensure high-quality and highly consistent results. This ability to achieve such refined welds reduces the need for post-welding finishing work, saving both time and effort.